We take pride in our state-of-the-art processing techniques, ensuring that every pipe and fitting we manufacture meets the highest standards.

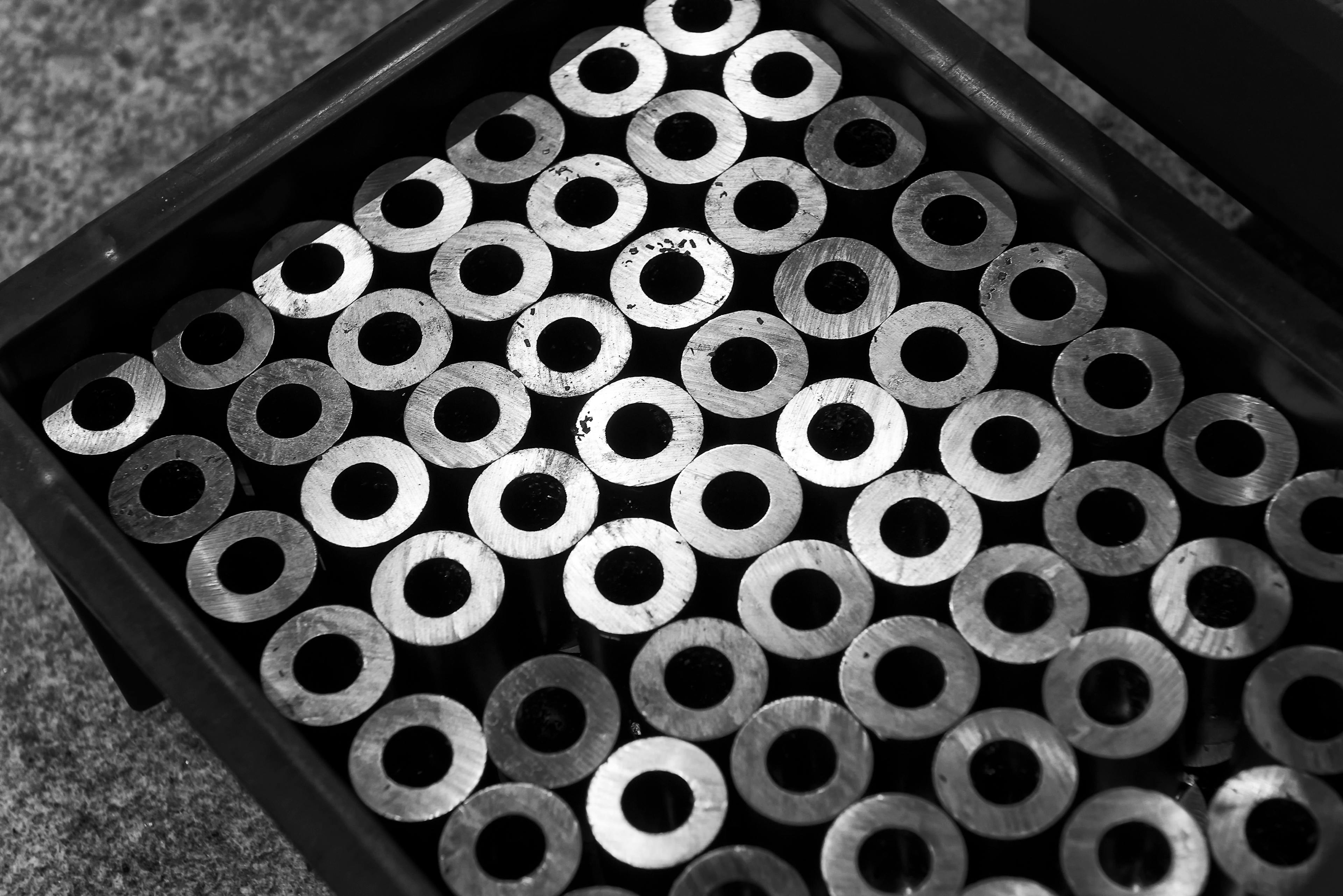

Hengtong currently has three cold drawing lines, which can process the pipes with OD 70-470mm and a WT 5-30mm. The products are suitable for fields such as gas cylinder pipes for mechanical engineering, drilling pipes for O&G, and construction machinery cylinders that require the high precision of OD and WT. Over 10 years we have been serving many significant end users in China such as Dezhou Continental Shelf Petroleum Engineering Technology Co., Ltd., Sinopec Jiang Diamond Oil Machinery Co., Ltd., XCMG Engineering Machinery Co., Ltd., Tianjin Lilin Petroleum Machinery Co., Ltd., etc.

Hengtong can provide both of boring and honing service. It's mainly used for products, which have strict requirements for inner roughness and diameter uniformity, such as construction machinery, O&G, screw drilling tools and precision pipes in the chemical industry, etc. Feasibility: OD 100-370mm, WT 5-20mm, Length up to 8 meters, and the roughness RA≤0.5um

The main function of this service is to blast the outer surface of pipes and tubes and remove impurities such as scales on the outer surface after heat treatment. We can treat pipes and tubes with OD 50-400mm and length up to 8 meters.

We give full satisfaction meeting customer's requirements in terms of operating performances and straightening quality. Our fully automated point and continuous straightening machines can straighten tubes ranging from OD 60-400mm with straightness of M/0.5mm

In our mill, we can carry out open air and closed heat treatment on pipes in wide dimension range. The pipes are inductively heated in a continuous process, followed by air cooling. This gives them the required strength and toughness.

At Hengtong, we prioritize the quality of our products. To ensure this, we conduct a range of rigorous tests. This includes:

We conduct Non-Destructive Testing (NDT) and Destructive Testing (DT) to verify the structural integrity and longevity of our products without causing any damage. This helps us deliver products that can withstand the most challenging environments.

Our Ultrasonic Testing (UT) is an advanced method that enables us to detect internal and surface defects. This state-of-the-art technique provides accurate and reliable data, enabling us to maintain the highest product quality.

Through Positive Material Identification (PMI), we ensure that our products meet the specific chemical composition requirements. This testing helps us to maintain strict compliance with industry standards and client specifications.

We perform a comprehensive mechanical property test to determine the durability, elasticity, and strength of our products. This ensures they are fit for their intended application.

Understanding that every client's needs are unique, we offer customized testing services to meet specific requirements. Let us know what you need, and we will tailor a testing solution to meet your needs.

We believe that the quality of a product is as good as the raw materials from which it is made. At Hengtong, we diligently source our materials from reliable suppliers to ensure their quality and sustainability. We maintain a strong relationship with our suppliers and conduct rigorous checks to ensure the materials meet our high standards. Each material is handpicked with care, ensuring it complements our production processes and matches our commitment to quality, durability, and performance.